Control of Solvent Emission in Screen Printing

| Richards of Hull Control of Solvent Emission in Screen Printing |

|

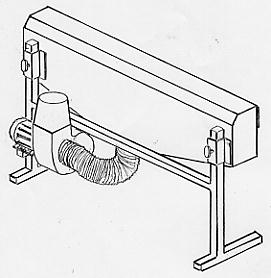

The print-table fume-catcher, with integral fan unit, can be positioned

and installed within the print room and connected with flexible ducting

to an exit louvre to remove fumes from the workplace. Alternatively, the air may be treated, and the contaminants removed. Not only trapping the solvent fumes, this returns clean air back into the building, avoiding the loss of heat in the air that would have been discharged. |

|

|

Connected to a Screen Table Fume Catcher or with single or two arm collector hoods for localised ventilation, the ICAF air treatment units reduce atmospheric pollution by employing activated carbon filtration. |

|

Localised Air Treatment Filtaire recirculation systems trap particles down to sub micron levels, removes pollen and airborne bacteria and absorbs smells and gasses. Information on the Filtaire range |